Specialty Machine Tools

Finepart makes premium machines for ultra precision manufacturing. Their machines use micro abrasive waterjet for drilling, cutting, milling and turning.

Visit their website or contact us to learn more about their precision waterjet cutting machines.

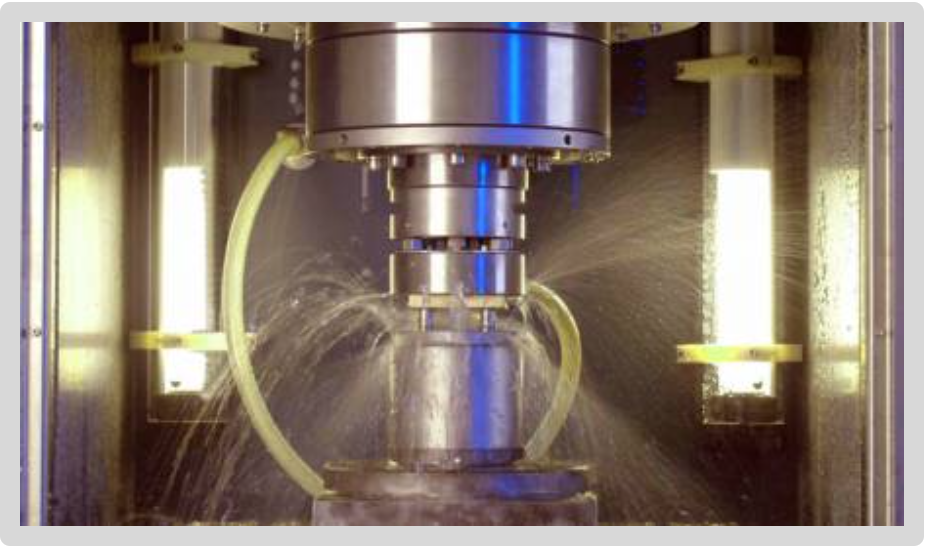

The Laser MicroJet (LMJ) is a hybrid method of machining, which combines a laser with a “hair-thin” water jet that precisely guides the laser beam by means of total internal reflection in a manner similar to conventional optical fibers. The water jet continually cools the beam and efficiently removes debris. As a “cold, clean and controlled laser”, Synova’s technology resolves the significant problems associated with dry lasers such as thermal damage, contamination, deformation, debris deposition, oxidation, micro-cracks and taper. From Aluminum to diamond, it will cut it strait, with burrs and with a nice finish.

Visit the SYNOVA website to learn about their offerings and contact HS&S for help in selecting the best solution to meet your needs.

We offer the High Precision Machining Center UVM Series from Shibaura Machine, who has been manufacturing high-precision industrial machinery for 70 years. .

Visit the Shibaura Machine website to learn more about its offerings including the High Precision Machine Center series and contact us for help in selecting the best solution to meet your specific needs.

Delete offers Dry electropolishing equipment for high performance and superior finishing applications.

Visit their website or contact us to learn more about the Dry Electropolishing system..

Following the principles of “Diligence, Honesty, and Reliability,” Para Mill makes an all-out effort to maintain their professional image and to provide topnotch double-sided milling machines, horizontal milling machines, and milling head units. Many years have passed since they began, and they have become highly reputed as a reliable.

Visit their website or contact us to learn more about their precision waterjet cutting machines.

Broaching Machines

AXISCO is the #1 Broaching Solution Provider and Broach Machine Manufacturers in Taiwan. Since 1984 Axisco has been a technology-driven company Known for focusing on customer needs..

Learn more about AXISCO broaching machines on their website, and contact us to learn specifics and find out if they have the best solution for your needs and requirements.

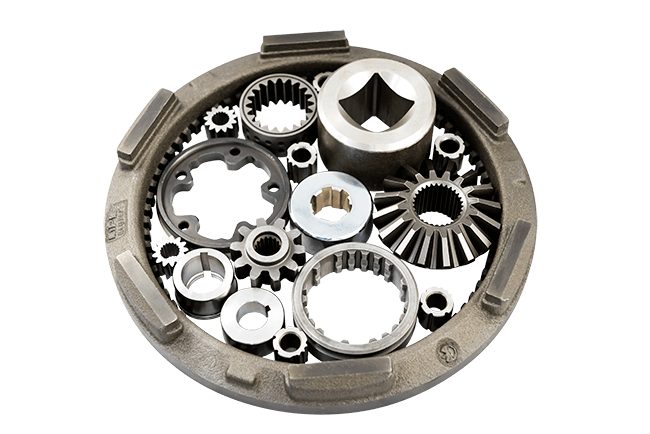

Precise Electrochemical Machining (PEM) is a powerful, non-contact metal shaping process that pairs a PEM Machine with an electrolyte processing unit, power generator, and operator control station. Using electric current and an oscillating tool bathed in a conductive electrolyte (salt water), PEM dissolves metal by liquefication. A positively charged workpiece (the anode) takes the form of the negatively charged tool (the cathode) as the metal is dissolved. The result is a high quality, burr-free part.

Visit PEM Technologie's website to learn about their products and contact HS&S for help in selectiing the solution that best suits your needs and requirements.